Publishers note: This feature originally appeared in our March / April 2014 Print Magazine.

By: Lloyd Clark

A CITY BUILT

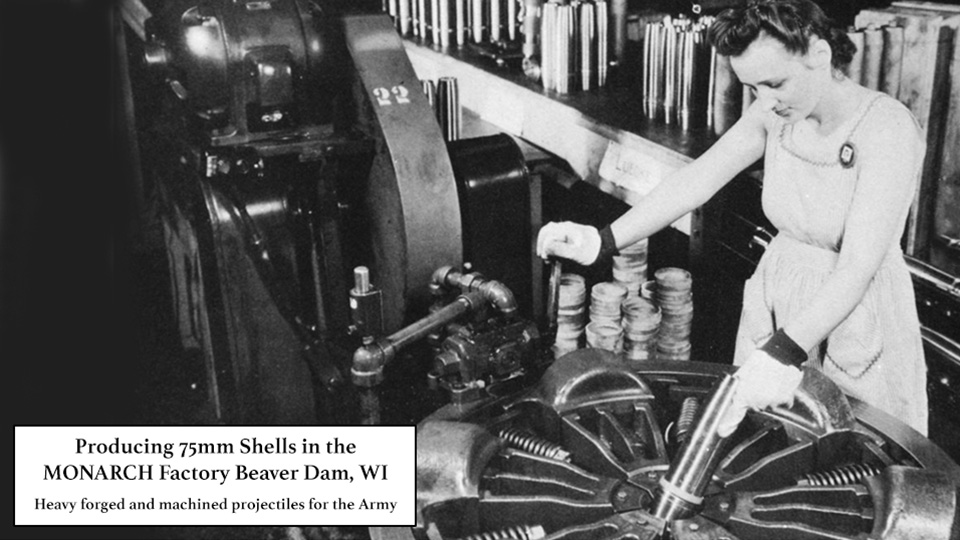

For nearly a century, the Malleable Iron Range Company, called Monarch by most after their extremely popular stove, towered above the east side of Spring Street on land that Rechek’s Food Pride now stands. On eight and one-half acres, the 430,000 square foot factory provided much more than stoves to the residents of Beaver Dam; it provided jobs, homes and livelihood to generations of our citizens.

Monarch did not start out in our fair city. No, the founders Silas McClure and A.C. Terrell started their business in 1896 in St. Louis, Missouri. When they formally incorporated the business in 1899, they used “Monarch” as their trademark and a legend was born.

In the early 1900s, Beaver Dam already had an iron manufacturing company: Beaver Dam Malleable Iron Works owned by local lawyer (judge, city official, State Assembly Representative, U.S. Commissioner of Lands, Civil War Veteran and President of the German National Bank) Silas W. Lamoreux. Lamoreux, having been contracted by the Dauntless Stove Manufacturing Company, a Nebraska company, to provide $5000 worth of parts for their stoves, suddenly found himself as owner of the Omaha corporation when they failed to be able to pay. Never one to pass up an opportunity, Lamoreux moved all of the company’s tangible assets, machinery, equipment and product to Beaver Dam, and as a result, 113 years ago the Dauntless Manufacturing Company was formed.

Dauntless, successful in getting a contract to produce stoves for the Army, attracted the attention of McClure and Terrell, and on February 2, 1902, they finalized a deal combining the two companies into the Malleable Iron Range Company (Monarch). Moving manufacturing to Beaver Dam created a business entity that would employ thousands of our citizens over the convening decades; however, the “renaming” of the company brought about a circuit court case when the “middle men” in the Army stove contract attempted to back out of the deal.

What’s In A Name?

Francis Buzzacott and Charles Pusey were partners in a business that actually secured the government contract. On November 19, 1901, they contracted with Dauntless “to manufacture army ranges and deliver them to Buzzacott, f.o.b. (free on board) cars at Beaver Dam, for $20 each.” On June 17, 1902 (after the official name change and the bill for the first installment of payments) Buzzacott and Pusey “executed and delivered an instrument in writing,” i.e. a contract, specifying that the total of the contract would be for no more than $3200 and that they were accepting the terms of the Beaver Dam Malleable Iron Range Company. In August of 1902, Buzzacott contacted Monarch stating that there were damage issues with many of the ranges and that he wished to cancel the contract immediately, for cause. Monarch agreed with the acknowledged stipulation that Buzzacott and Pusey would purchase the stoves already made. Buzzacott was to come to Beaver Dam and personally inspect each stove before they would ship it. This apparently transpired as written and on August 30, 1902, Buzzacott owed Monarch $3200.

In the journal, Reports of Case Law and at Chancery of the Illinois Supreme Court, 1910, on the case Malleable Iron Range Company vs. Pusey, it states that “Francis H. Buzzacott owed the Malleable Iron Range Company upward of $3200, and demand having been made upon Pusey for payment to the extent of $3200, and payment having been refused, an action of debt was commenced by the Beaver Dam Malleable Iron Range Company, a corporation, against Buzzacott and Pusey, in the superior court of Cook county (Illinois).”

From the records, it appears as if it was Pusey, and not Buzzacott, that was refusing to pay for the delivered stoves. After losing in court, Pusey pled the case to the Illinois Supreme Court, basing his appeal on the delivery of subpar product and the fact that the contract had been with the Beaver Dam Malleable Iron Range Company not with Malleable Iron Range Company. The Justices refused the subpar product statement, “This evidence the court excluded, upon the ground that all controversies with respect to defects in the ranges or damages suffered by Buzzacott by reason of any such defects had been settled by the acts and agreements of contracting parties.” They further denied that the contact would be null and void due to a misprinting of the company’s name, as this was already a set piece of case law as it was common during the early years of the United States for contractual “typos” to appear in handwritten documents. In the end, Pusey ended up paying Monarch more than $4000 for the stoves delivered and their legal fees.

Monarch employed 20 people in 1902, and that number grew somewhat slowly during the early years of the company. Up until 1910, Monarch had purchased most of the cast iron parts for the stoves and heaters they built. In that year, they added a foundry to the factory and began to produce 100% of their own parts. They would later add a warehouse, as well as multiple buildings dedicated to fabrication, annealing, a machine shop, and then an even larger warehouse when production took off. Monarch expanded to multiple, semi-attached buildings that stretched from Rechek’s to the Shoe Factory. Monarch’s line of ranges moved out of merely the home market and became standard for restaurants, hotels, and in chefs’ kitchens the world over. More than 4500 retailers sold Monarch ranges and the company had grown to 26 departments.

Monarch ranges went literally to the ends of the earth as famous explorer Admiral Richard Byrd (who discovered the South Pole) personally visited the Monarch factory, worked with Monarch engineers to design a coal/wood burning stove for his second Antarctic expedition and an oil burning stove for his third. He then used both stoves in all his further expeditions.

Monarch inventor and President Herbert Burrow designed and patented the combination coal-wood-electric range in 1938. Never satisfied to rest on their laurels, Monarch developed and patented dozens of ideas. Their trademark stove moved from wood burning to coal burning to gas burning to electric powered. The 1950s brought in the rage for enamel and chrome appliances and Monarch once again led the way. By the mid-1950s, Monarch employed 1,200 and became the standard for quality in stoves, refrigerators, heaters and water heaters. Many homes in Beaver Dam, including the author’s, still have Monarch gas or electric water heaters performing brilliantly.

Andrew Hill, Monarch’s first President, served in that position until 1921. Hill’s mansion, built around 1910, can still be seen at 1202 North Center. However, this is not the home’s original location. Many of us can remember back in 2005 when the home, which was then owned by Trinity Church on Oneida Street, was sold to a local resident who, along with the carriage house next door, had the entire building lifted from its foundation and moved ever so slowly up Center Street to its current location.

Fred W. Rogers became the next Monarch President in 1921, when he was elevated from the position of Vice-President by the Board of Directors. Rogers was extremely active in moving the company, and the community, forward. Known for his philanthropic efforts, Rogers also built a quaint little place near to the factory to allow visiting businessmen and dignitaries a place to stay – the Rogers Hotel.

Gone, But Not Forgotten

By the 1980s, Monarch had passed its peak as a corporation. By the time the doors closed for good in 1985, only around 250 employees still made the trek each day to the mammoth factory on Spring Street. In March of that year, Monarch filed for bankruptcy and its assets were sold off in July of that same year.

Unfortunately, Monarch left another legacy for Beaver Dam, that of a toxic waste “brownfield.” For decades, Monarch had proudly stated the use of asbestos in their products. Unfortunately, this was before science understood the detrimental effects that asbestos has upon the human body when inhaled. Further, the Wisconsin Department of Natural Resources found more than 500 barrels of toxic waste when they toured the closed factory in 1986. When the corporation that had bought out the assets of Monarch refused to be held accountable for disposal of the toxic chemicals, the Environmental Protection Agency stepped in and used Superfund money to “clean” the site.

In 1990, a fire destroyed a large portion of the decaying buildings. The city, which had taken over ownership of the property, went ahead and leveled the buildings. While this may have been the end of Monarch’s era in Beaver Dam’s metal fabricating history, it was by no means the end of metal fabricating in Beaver Dam. Our city is dotted with metal shops from Beaver Blacksmith and Welding to Breuer Metal Craftsmen and Phoenix Coaters. As long as there is a need for custom crafted metal products, our proud Beaver Dam craftsmen will be there to supply those needs.

Beaver Dam may not be the manufacturing “giant” that we once were; however, we can take pride in the knowledge that the “can do” attitude and drive to succeed still exists in our town. Monarch may be gone, but the dream, along with the drive and the determination that built a world-leading manufacturing plant, is still here – and is not forgotten.